Sicherheitstechnik: Sicherheit für Menschen, Maschinen und Prozesse – seit über 30 Jahren

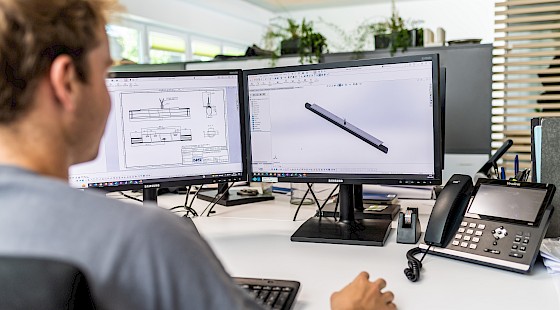

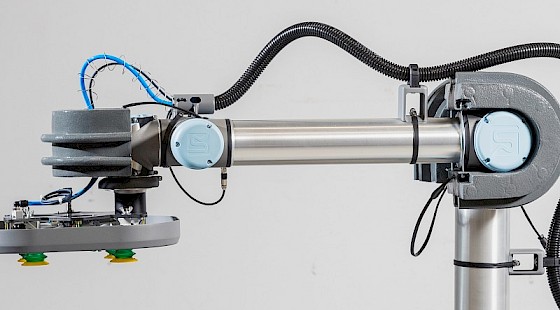

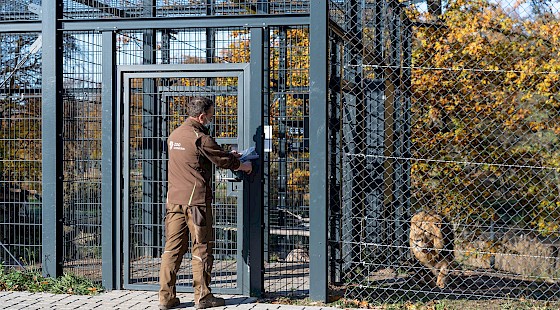

Die Haake Technik GmbH ist seit mehr als 30 Jahren in der Entwicklung und Fertigung von Sicherheitstechnik erfolgreich tätig. Wir entwickeln und fertigen Schaltleisten, Safety Bumper, Schaltmatten, Schalter, Türverriegelungen und Ventilverriegelungen. Unser Familienunternehmen legt größten Wert auf enge Zusammenarbeit mit den Kunden. So entstehen im Dialog immer wieder neue Ideen, um noch bessere Lösungen für beispielsweise kabellose Türverriegelungen, Sicherheitsschalter und Kontaktleisten zu entwickeln.

Mit unseren weltweiten Niederlassungen und Vertriebspartnern sind wir in der Lage auch den internationalen Markt mit qualitativ hochwertiger Sicherheitstechnik wie Schaltleisten, Bumper, Schalter bzw. Sicherheitsschalter, Schaltmatten oder Verriegelungssystemen zu bedienen. Arbeitssicherheit und Maschinensicherheit haben für uns oberste Priorität.

Ob Schaltleiste, Safety Bumper oder Sicherheitsschalter sowie Türverriegelung, Schaltpuffer oder Sicherheitsventilverriegelung, wir tragen dafür Sorge, dass Sie mit unseren Produkten Ihre Arbeit sicherer gestalten. Einen ersten Eindruck über die Möglichkeiten und Produkte, die wir Ihnen bieten, erhalten Sie auf unserer Internetseite.

Wir freuen uns auf Ihren Auftrag.

Von Anfang an gut beraten: Wählen Sie den für Sie geeigneten Fachvertreter aus!